Mud pump power end components

Product

The brand designs are:

Hot products:

Mud pump power end components

|

|

|

|

|

|

|

|

|

Ⅰ . Power End (frame, pinion shaft, crankshaft, crosshead and extension rod)

1. Power end features:

.Continuous tooth herringbone gear.

.One-piece alloy steel crank.

.Renewable crosshead guide.

.The frame is made of welded steel plate to provide the frame with high strength, good rigidity and light weight. The extension rod packing is duplex seal structure to provide the good seal result. The power end uses the combined lubricating system of forced lubrication and splash lubrication.

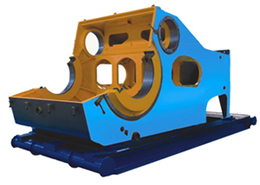

2. The frame:

The frame is made of welded steel plate and stress relief treated to obtain

the good rigidity and high strength. The place where the crankshaft bearing

is fitted is strengthened by using ribbed plates. The frame is furnished

with the necessary oil basin and oil way system for cooling and lubricating

purpose.

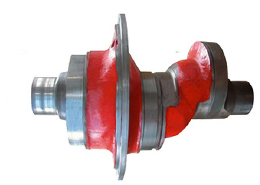

3. Crankshaft

The crankshaft is made of cast alloy steel and furnished with herringbone

gear, connecting rod and bearing. The tooth form of the big geared ring is

herringbone gear. The gear bore and the crankshaft surface are interference

fitted and they are both fastened with bolts and lock nuts. The big end of

the connecting rod is mounted on three eccentric straps of the crankshaft

through single row short cylindrical roller bearings and the small end on

the crosshead pin through double row long cylindrical roller bearing. Double

row radial spherical roller bearings are mounted at both ends of the

crankshaft.

4. Pinion shaft

The pinion shaft is made of forged alloy steel, on which a herringbone gear

with the medium-hard tooth surface is machined. For easy maintenance, the

single row radial long cylindrical roller bearing with inner ring (without

sides) is used. The both ends of the pinion shaft are extended out so that

the sheave or the sprocket can be mounted on either end.

5. Crosshead and Extension Rod

The crosshead and crosshead guide are made of ASTM A48-83 meehanite cast

iron featured by good abrasion resistance and long service life. The

connection between the crosshead and the extension rod is made by using

bolted flange. The rigid connection ensures the concentricity of the

crosshead and the extension rod. The coupling is used for connecting the

extension rod to the piston rod. The light-weight coupling enables the

extension rod and the piston rod to connect to each other easily and

reliably.

II .Spraying System

The spraying system consists mainly of spray pump, cooling water box and

spray pipe. the function is to cool and rinse liners and pistons to promote

their service life.

The centrifugal spray pump can be driven by a sheave mounted on the input

shaft extension end or a separate motor and cooled and lubricated by water.

The spray pipe is mounted on the coupling between the extension rod and the

piston rod and can reciprocate with the piston. Nozzle is near the piston

end so that the lubricating-cooling fluid can rinse the contact surface

between the piston and liner all the time. The durable fixed spray pipe may

be used, too.

III .Lubricating System

The power end uses the combined lubricating system of forced lubrication and

splash lubrication. The pressure oil is conveyed through lubricating

pipeline, crosshead, extension rod, crosshead guide and all bearings by a

gear oil pump within the oil box to realize the forced lubrication. The

working condition of the gear oil pump may be understood from the pressure

gauge behind the frame.

Ⅳ .Charging System

To prevent the air lock occurring for low pump inlet pressure, every mud

pump is furnished with a complete charging system. It consists of charging

pump, pump base, butterfly valve and corresponding manifold. Mounted on the

suction manifold of the mud pump, the charging pump is driven by the special

purpose motor or the input shaft of the mud pump through V-belts to reduce

the power consumption.